| CLICK HERE FOR INDEX PAGE | ||

| HEALTH AND SAFETY - RISK ASSESSMENTS | ||

| V. Ryan © 2014 | ||

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | ||

|

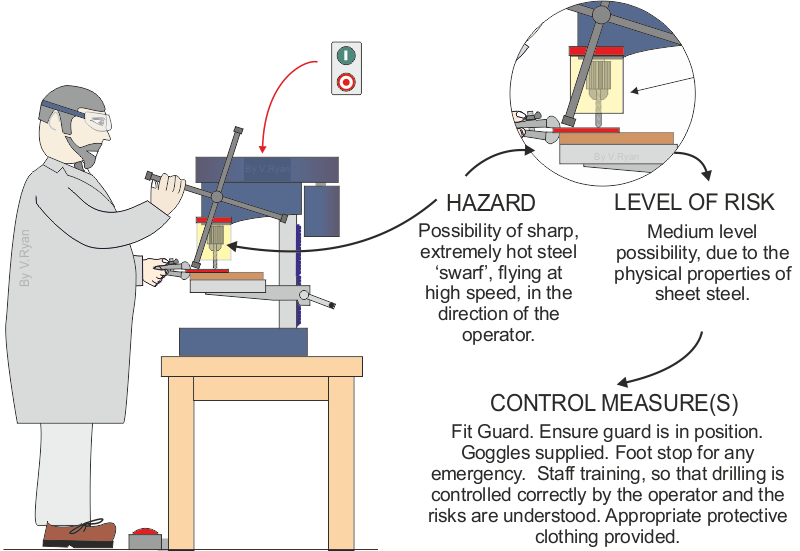

According to the Law, employers must ensure the safety of their workforce.

One way of doing this, is for the employer to assess the risks involved in

the various jobs and processes, carried out by their workers. For example, a worker may operate a drilling machine, to ‘drill’ holes in sheet steel. The employer must assess the risks to health and safety, at every stage of operation. Appropriate precautions are then introduced, to protect the employee from harm and injury. Two of the main aspects of carrying out a risk assessment, is to identify the hazards. These are activities that are potentially dangerous. Once an hazard has been identified, the risk (or possibility) of an employee being harmed by the hazard, is quantified. This is usually recorded as low risk, medium risk or high risk. |

||

| SAMPLE RISK ASSESSMENT | ||

|

||

|

||

| HOW THE INFORMATION IS RECORDED IN A TABLE | ||

|

HAZARD |

RISK - LEVEL | CONTROL MEASURE(S) |

|

Possibility of sharp, extremely hot steel ‘swarf’, flying at high speed in the direction of the operator. |

Medium level possibility, due to the physical properties of sheet steel. | Fit Guard. Ensure guard is in position. Goggles supplied. Foot stop for emergency. Staff training, so that drilling is controlled correctly by the operator and the risks are understood. Appropriate protective clothing provided. |

|

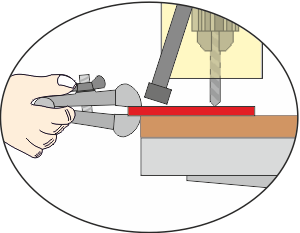

When drilling thin materials such as sheet steel and perspex, it is

necessary to secure the work in vice, or to clamp it down. Complete the table below by identifying the risk level and any necessary control measures. |

|

|

Click here for information about the drilling machine |

||

|

HAZARD |

RISK - LEVEL | CONTROL MEASURE(S) |

|

When holding sheet material in the hand whilst drilling, the materials can be gripped by the drill bit and spin round at high speed. It is possible for the sheet materials to ‘fly’ in any direction at high speed. |

||

|

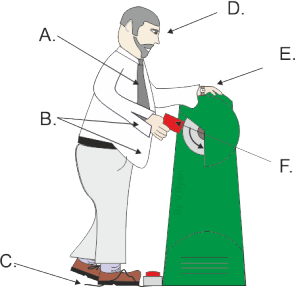

Study the buffing machine / polishing machine seen opposite. Identify two hazards. In your opinion, what is the level of risk for each of the hazards. What could be the control measures for each hazard / risk? |

|

|

|

Click here for information about the buffing machine |

||

|

HAZARD |

RISK - LEVEL | CONTROL MEASURE(S) |

|

|

||

|

|

||

|

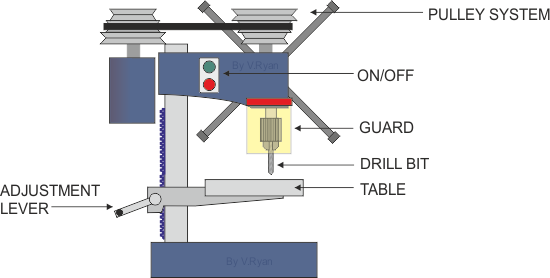

Carefully study the bench top machine drill (seen below). Identify the hazard, relating to the belt system / pulley system. In your opinion, what is the risk level? Describe control measures that could be applied to minimise the hazard/risk. |

||

|

||

|

||

|

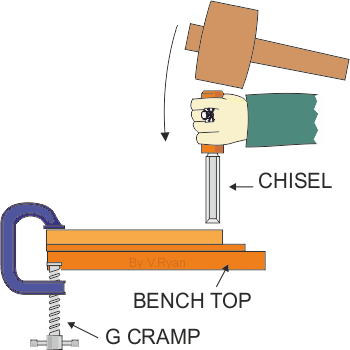

Carefully study the chiselling process (seen opposite). You may need to

research marking out and cutting finger joints / dovetail joints. Identify the hazards, relating to the chiselling process. In your opinion, what is the risk level for each of the steps? Describe control measures that could be applied to minimise the hazards/risks. Record your findings in a table. |

||

|

||

| CLICK HERE FOR PRODUCT DESIGN INDEX PAGE | ||