| CLICK HERE FOR INDEX PAGE | |||

| BASIC MANUFACTURING OF THE EAMES LOUNGE CHAIR ALUMINIUM PARTS / COMPONENTS |

|||

| V. Ryan © 2011 | |||

|

The main parts / components of the chair are the cast aluminium base and

frame/support and the plywood / veneer forms, including the head rest,

back rest and seat. The aluminium parts are cast from aluminium ingots and recycled aluminium. The plywood / laminated forms are manufactured through steam bending of the layers of veneer. |

|||

|

|||

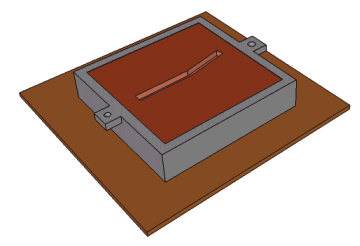

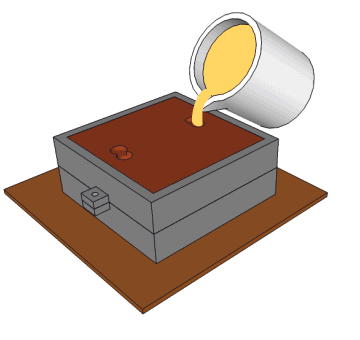

| 1. PREPARING THE CASTING BOXES | 2. POURING THE MOLTEN ALUMIINIUM | ||

|

A wood pattern of the aluminium part is made. A casting box (mould) is

prepared in sand, using the wooden pattern. When the sand casting box is

complete, the pattern is removed, leaving a cavity in the sand The example below shows the preparation of the casting box for the aluminium frame / support of the chair. |

A top casting box, called a ‘cope’ is placed in position. Molten aluminium is poured into the cavity left by the wooden mould. | ||

|

|

||

| MACHINING | |||

| When cool, the aluminium castings are removed from the sand. They are finished by machines such as a vertical miller and hand tools. A horizontal miller and shaping machine could also be used (vertical miller recommended). | |||

| For further information on casting and machining, click on the links below: | |||

| CASTING ALUMINIUM | |||

| Foundry Work 1 (Casting 1) | |||

| Foundry Work 2 (Casting 2) | |||

| Foundry Work 3 (Casting 3) | |||

| Foundry Work 4 (Casting 4) | |||

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET ON THE CASTING PROCEDURE | |||

| MACHINING | |||

| The Vertical Miller (1) | |||

| The Vertical Miller (2) - Making Adjustments | |||

| The Vertical Miller (3) - More Information | |||

| PDF FILE - CLICK HERE FOR VERTICAL MILLER PRINTABLE WORKSHEET | |||

| The Horizontal Milling Machine - 1 | |||

| The Horizontal Milling Machine - Cutters and Up-Milling - 2 | |||

| PDF FILE - CLICK HERE FOR PRINTABLE HORIZONTAL MILLING MACHINE WORKSHEET | |||

| The Shaping Machine | |||

| CLICK HERE FOR PRODUCT DESIGN INDEX PAGE | |||